Today, between 20% and 50% of the energy used in industry is lost as waste heat. However, this wasted energy can be recycled and the loss can be reduced to a minimum. Recovering heat can be achieved via numerous technologies and investing in one is extremely cost-efficient. The system is also great for reducing greenhouse emissions which is crucial for the environment, especially with the rising concerns for global warming in recent years. Here are some things to know about waste heat recovery systems.

What is waste heat?

The energy that is lost and expelled into the environment due to not being put into practical use is considered wasted heat. It occurs from the inefficiencies of equipment and operations, but around 80% of it can be recovered and used for a different purpose using specialized systems.

What is a waste heat recovery system?

These technologies are used to recover heat that is usually wasted turning them into valuable energy sources and reducing the overall energy consumption in the process. They extract energy from a process and transfer it with a gas or liquid back to a system. This converted energy can be repurposed to provide additional heating or it can be used as electrical power.

What are the most popular types?

1. Recuperators

They are made from metal or ceramic materials and recover waste heat in medium to high-temperature applications. It preheats the inlet gas before it enters the process and decreases energy demand as well.

2. Regenerators

They are suited for high-temperature applications with dirty exhausts. The heat is regenerated and reused in the process when using this kind of waste recovery systems.

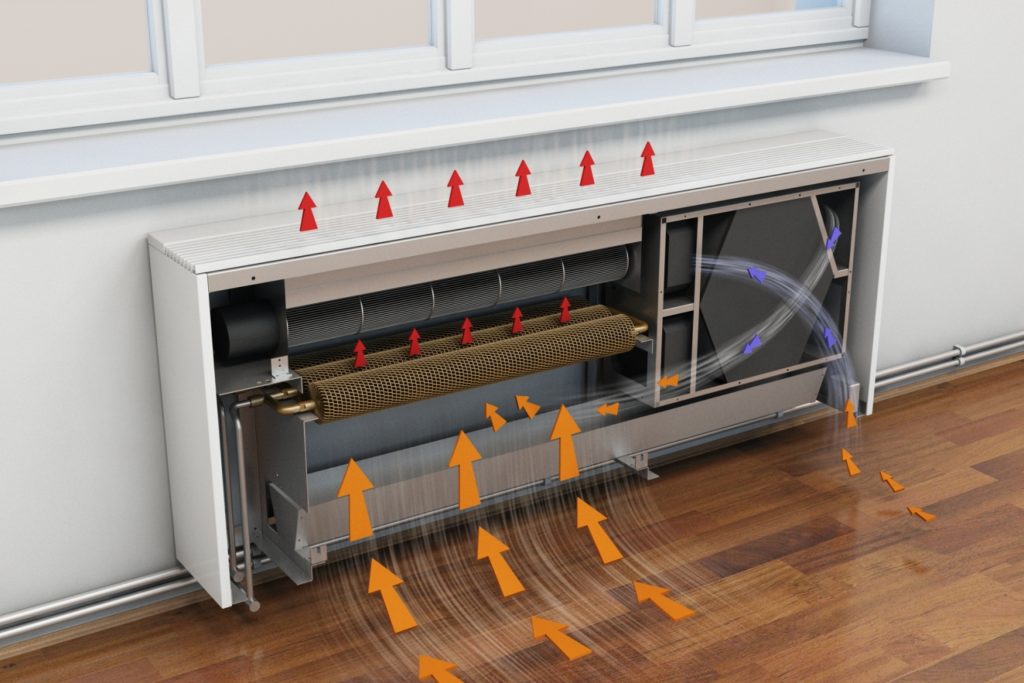

3. Rotary Regenerators (Heat Wheels)

A regenerative heat exchanger can be designed to not only recover heat, but also moisture from clean gas streams. Its main application lies in air conditioning and space heating systems and it uses a rotating porous disc where it stores heat. The disc is placed over two parallel ducts, one that contains hot waste gas, while the other contains cold gas and it alternates the flow of gasses through the regenerator.

4. Economizers

They are used for heating liquids by recovering waste heat that is low to medium in temperature. They can be used to preheat boiler feedwater, hot process liquids, provide hot water for space heating or domestic use.

What are the benefits

Installing one of these systems into your office, house, or industrial site can offer numerous benefits. Since most of the wasted heat can be recovered, it drastically reduces energy consumption and its cost as well. Less heat is wasted also due to lower flue gas temperatures in the chimney. It reduces emission levels, carbon dioxide, and drastically improves indoor air quality.

Making this small change and implementing one of these systems in your facility can have a large impact on efficiency. Reusing waste is also a great way to conserve resources and reduce pollution, especially since some of these systems can eliminate the need for another heat source.

Conclusion

Waste heat recovery systems are great for the conservation of energy and resources. Investing in one will not only be repaid in just a few years, but it can help you save money, have better indoor air quality in your facility, and also have an extremely positive environmental impact. If you want to learn more about this topic, visit this website.