Extrusion is an industrial process that allows the creation of objects with a constant cross-section, such as tubes, sheets, profiles, and bars, by shaping the material through plastic deformation. It is a technique used to process materials that are plastic enough to deform without breaking, such as polymers and metals.

The first applications of extrusion date back to the early 1700s, but it was only after World War II that this process became widespread. Its development was determined by the arrival on the market of new thermoplastic materials, such as polypropylene and polyethylene, which, thanks to their low cost, ease of processing, and good mechanical properties, made extrusion particularly advantageous in various industrial sectors.

How Does Extrusion Work?

The extrusion process consists of pushing a material, which has been made into a paste or melted, through a die (or die head) that determines its final shape, usually a constant section such as tubes or bars. Upon exiting the die, the material is cooled or, in the case of rubber, vulcanized to stabilize its shape.

There are two main types of extrusion: direct and reverse. In the first case, the material is compressed forward by a piston and exits from the opposite side, passing through the die. This method is very common and allows high pressures to be exerted, although it requires greater force due to the friction between the material and the walls of the container.

Reverse extrusion, on the other hand, involves the die being connected to a piston, which compresses the material, causing it to exit in the opposite direction to its movement. This system reduces internal friction, as the material does not flow along the walls of the container, and ensures more stable pressure throughout the cycle.

What is an Extruder?

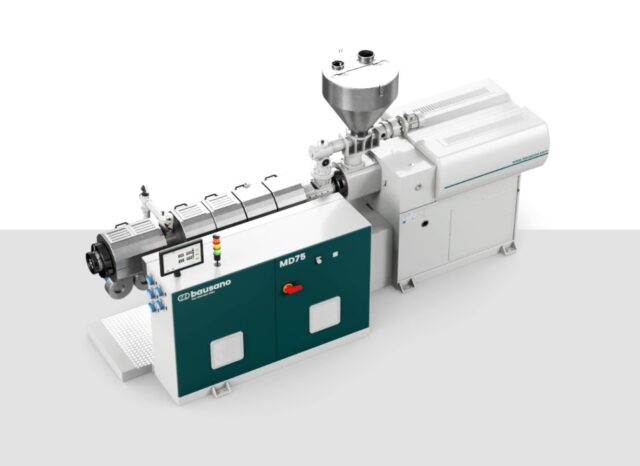

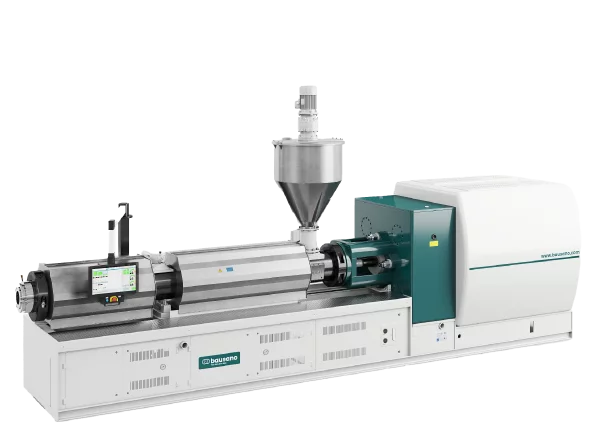

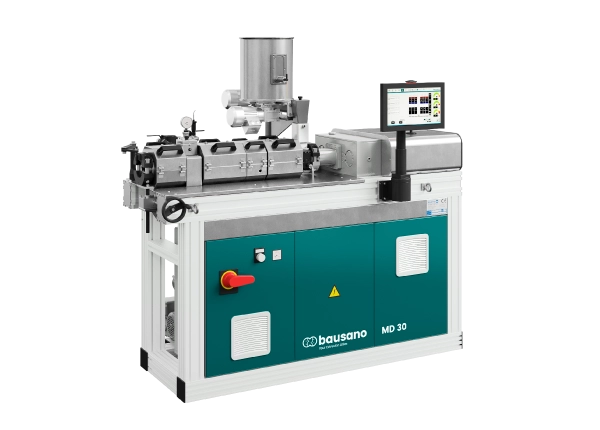

The extrusion process requires the use of a specific piece of equipment called an extruder. This tool mainly consists of a nitrided steel cylinder inside which one or two endless screws rotate (in fact, we refer to twin-screw extruders or single-screw extruders). It is also equipped with a hopper at the entrance to the cylinder, from which the material can be loaded, and a die, or die head, which gives the extruded product its final shape.

Inside the extruder, the material undergoes a series of thermal and mechanical transformations thanks to three functional zones. In the feed zone, the plastic or metal begins its journey without significant changes in pressure. It then passes through the compression zone, where the pressure increases significantly due to the progressive enlargement of the screw core, promoting compaction and initial melting. Finally, the material reaches the metering zone, where the pressure stabilizes, allowing a constant flow towards the die.

At the same time, however, the material passes through three physical states: in the solid transport zone, it is still intact and is cooled with water to prevent it from melting too early. In the transition zone, on the other hand, it begins to melt due to friction and heat generated by electrical resistance. Finally, in the melt transport zone, the material is completely melted and ready to be pushed through the die, thus taking on the desired shape.

Which Extruder Should Be Used?

As already mentioned, a single-screw or twin-screw extruder can be used to carry out the extrusion process, depending on the production requirements and the characteristics of the material to be processed. In the first case, the material is drawn along the production line by the rotary movement of the single screw, which pushes and heats the polymer as it advances. This type of machine is suitable for standard processes and the processing of relatively simple materials.

In contrast, twin-screw extruders use two screws working in synergy to transfer and homogenize the material. In this case, the degree of advancement depends on the distance between the screws and their configuration. Compared to single-screw extruders, twin-screw extruders offer superior performance in terms of mixing, homogenization, and versatility. For this reason, they are more suitable for processing complex raw materials, modified mixtures, and/or heat-sensitive materials, as they allow for better control of operating conditions.

Furthermore, twin-screw extruders can be distinguished according to the direction of rotation of the screws: in co-rotating models, both screws rotate in the same direction, ensuring more efficient mixing and a more homogeneous flow, while in counter-rotating models, the screws rotate in opposite directions, ensuring greater compression force. The choice between the two options depends on the type of application, the properties of the material to be processed, and the desired performance.

What Should You Pay Attention to During the Extrusion Process?

To achieve optimal results with the extrusion process, it is necessary to pay attention to a few details. The first point concerns the material immediately after it leaves the mold. At this stage, in fact, a slight swelling may occur, which can affect the final dimensions of the piece.

However, by calibrating the equipment properly, it is possible to control this phenomenon, obtaining defect-free objects. Furthermore, it is essential to pay attention to the choice of materials, especially when using recycled plastics.

Although recycled plastics are a sustainable choice, they can have slight variations in their physical and chemical properties, as well as some residual impurities. To ensure the quality of the finished product, it is therefore advisable to carry out thorough quality checks and, if necessary, add virgin material.

Finally, it should be noted that the production of very complex or particularly narrow profiles can present certain problems. In these cases, it is essential to carefully evaluate the type of equipment to be used, as not all systems are suitable for ensuring the required level of precision.