A welding torch is a mechanical tool used in the welding process to join two parts together. The torch creates an open flame using gas, fuel, and oxygen. Most torches are used in large factories and industries, but you can use them in your DIY projects. A welding torch can be used to cut, weld, or braze various types of metals.

Torch welding has been around for a long time, even before electricity. Though you can successfully weld without a welder, a welding torch is a necessary tool used in welding.

Welding torches are used in both electrical and gas welding. The electrical welding torch is used to supply an electric current to the electric rod, while a gas welding torch supplies a gas mixture as you weld. These torches come in different sizes and designs, depending on how you intend to use them.

Oxyacetylene Torches

Oxyacetylene welding torches have long metal rods that can either be straight or have a bend at the top. The long metal rod has pipes that allow the gas fuel and oxygen to flow freely. The pipes are attached to the gas and fuel and the oxygen tank. The bend at the top allows the welder to aim the flame properly.

The type of torch being used depends on the welding process. Two main types of welding torches are commonly used:

Positive Pressure Types

These are also known as medium-pressure types or equal-pressure types. They are the most common torches. They use both oxygen and fuel gas that burn at the tip of the torch to produce a flame.

Injector Types

These appear similar to positive pressure types. However, the oxygen pressure is higher and can use very low acetylene pressure, making them economical.

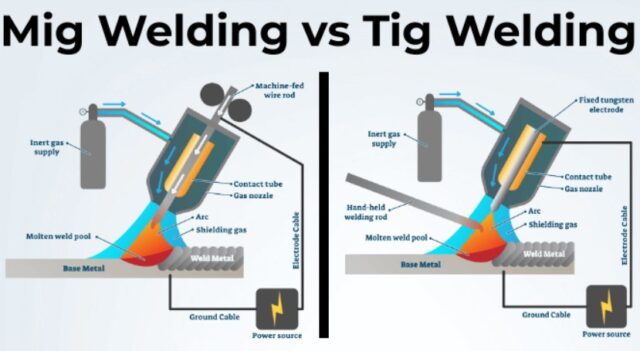

TIG vs MIG Gas Welders

Another distinguishing factor when discussing a welding torch is whether it is a tungsten inert gas welder (TIG) or a metal inert gas welder (MIG).

The TIG Welding Torch

This torch uses a tungsten electric rode that does not melt during the welding process. This torch is usually used when working with aluminum and stainless steel. The TIG torch also has a cap to shield the area being welded from contamination. The most common shielding gas used with this torch is Argon. Sometimes Helium is added to increase penetration.

The MIG Torch

This torch has a consumable electrode made of copper or steel. This torch is usually used on aluminum and mild steel. The two main shielding gases used with a MIG torch are pure argon or a combined mix of argon and carbon dioxide. When using this mix, the ratio should be a 75%-25% mix of argon and carbon dioxide respectively. Pure argon works well with aluminum, while the argon/carbon dioxide combination is best for mild steel or stainless steel.

Sometimes Helium is added to Argon, making it ideal when working with thick materials. Helium also works well in cold environments. However, Helium is quite expensive.

Torch Safety

Before using a welding torch, you need to adhere to the basic safety rules.

Follow Guidelines

You should always use the equipment for what it is intended for. Follow the manufacturer’s guidelines to avoid potential accidents. Study the manual before using the equipment to understand the guidelines.

Check Your Environment

Analyze your surroundings to make sure there are no potential hazards or flammable chemicals that can cause a fire. Ensure that you are in a well-ventilated room that can allow the fumes to escape. You should also ensure there is no one in harm’s way. Keep all cylinders away from living spaces.

Wear You Gear

Wear protective gear to prevent burns and other physical and toxic inhalation injuries. This includes long-sleeved gloves, long pants, welding shoes, and a welding helmet that appropriately covers your face. A respirator is necessary to avoid breathing in toxic fumes. Consider having welding fire blankets on hand.

Check for Leaks

Always check if there are leaks in the gas cylinder. If you smell rotten eggs or hear a hissing sound, there is probably a leak. You can also cover the connection area with soap to watch for bubbles.

Hold the Torch Correctly

Keep the torch away from your face by holding it upright at all times to prevent any flare-ups.

Before you fire up your torch, check to see that the torch valves are completely closed. Do not stand directly in front of the regulator.

Don’t Forget

Before you start using the torch, clean the material that is going to be welded. When you are ready to start, open the cylinder valves slowly and carefully. Attach the welding tip on the torch handle and turn on the gas fuel before then the oxygen one.

When working, do not bend over the welding torch. Ensure that your face is a way to avoid inhaling the fumes. When you are done using the torch, disconnect the fuel cylinder from the torch.