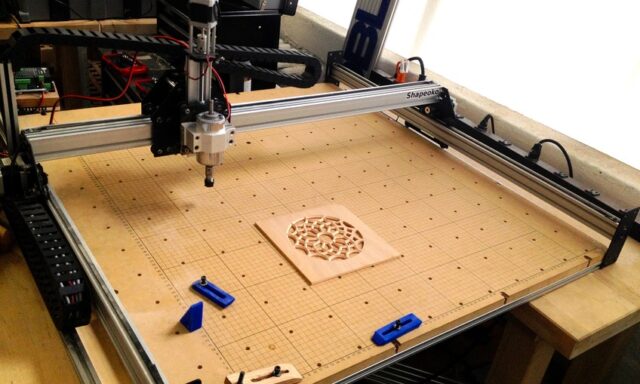

CNC machines have been around for a long time with their history going back to the ‘50s. During that time, the machines completely transformed the way people manufactured things.

They have also democratized the process, allowing up-and-coming engineers to create their own products. With such versatility it offers, you might be wondering if you can build your own CNC machine, and the answer is simple – yes you can. In this article, you will be able to read some tips on making your own CNC machine. Let’s take a look:

1What to Look Out for

Before buying kits or choosing components, it is important that you answer these questions:

1. What are you going to make with the machine? – Of course, these machines are versatile, hence, they can produce different products. However, you should consider what projects will you use the machine for. This decision will also help you in knowing what parts you will need to make it.

2. How much time do you have to build it? – The answer to this will come from whether you are interested in CNC as a business or a hobby. However, it is always better to spend more time building it.

3. How much are you willing to spend? – The answer will depend on whether you want to use it personally or professionally.

2A CNC Kit

A CNC kit will help you with building your machine. And that is mostly because the kit comes with everything you need to put the machine together.

Also, most of the kits will come with a wide range of customization options which will allow you to choose the right parts you need. If you are looking for parts for your CNC machine, visit ArtMachining.

3The Steps You should take when building a machine

The exact assembly process will depend on the type of machine you choose to build, however, there are some key steps that you should follow:

1. Design your machine – you should create a design for your CNC machine that will give you an idea on how the finished project will look like.

2. Get the Parts – once you have chosen the design, you can go onto buying the parts that you need for it.

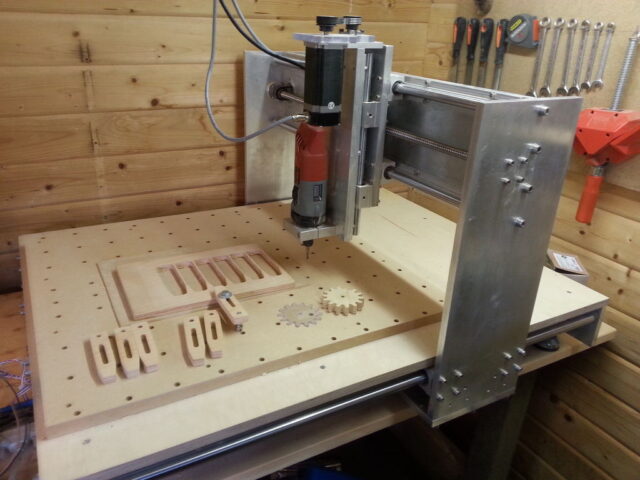

3. Construct the Frame – your frame will hold together your machine. Hence, the first thing you will do is to build the frame. Metals such as aluminum are good options since they are stable and rigid.

4. Bring in the Z-axis – your machine will be moving up and down along the Z-axis. But, you will need a place to house these tools. You will mount it to the gantry, which will give your tool depth.

5. …Then the X-axis – adding guide rails and bearings will help you keep the rigidity of your CNC machine, and it will allow your tool to move backward and forward along the X-axis.

6. Implement the Electronic Parts – you will now be able to add the heart of the machine – the electronic parts. The most important thing to add is the motor, PSU, drivers, breakout board, and processor.

7. Add your machining tool – there is a wide range of machining tools available. Metal cutting tools are the most common type, however, more advanced machines use plasma or laser cutting tools.

8. Start making things! – Since your machine will be completed, you will now be able to start working on your projects!

Conclusion

By following these tips, you will be able to customize your own CNC machine, save money, and create amazing things with this machine. Hence, do not waste any more time and start researching extensive guides on how to build your very own, CNC machine.